Project Portfolio

Welcome to my project portfolio! These projects provide examples of past engineering work in design, analysis, CAD and prototyping.

Each of the listed projects has a short description below its image. For those projects with more details, you can check out the project’s page by clicking on its image.

Portfolio Layout

(Click to Jump)

Mechanical Design/Analysis

Mechanical Design/Analysis

Acoustic Focusing for Non-Contact Assembly of Composites in Manufacturing

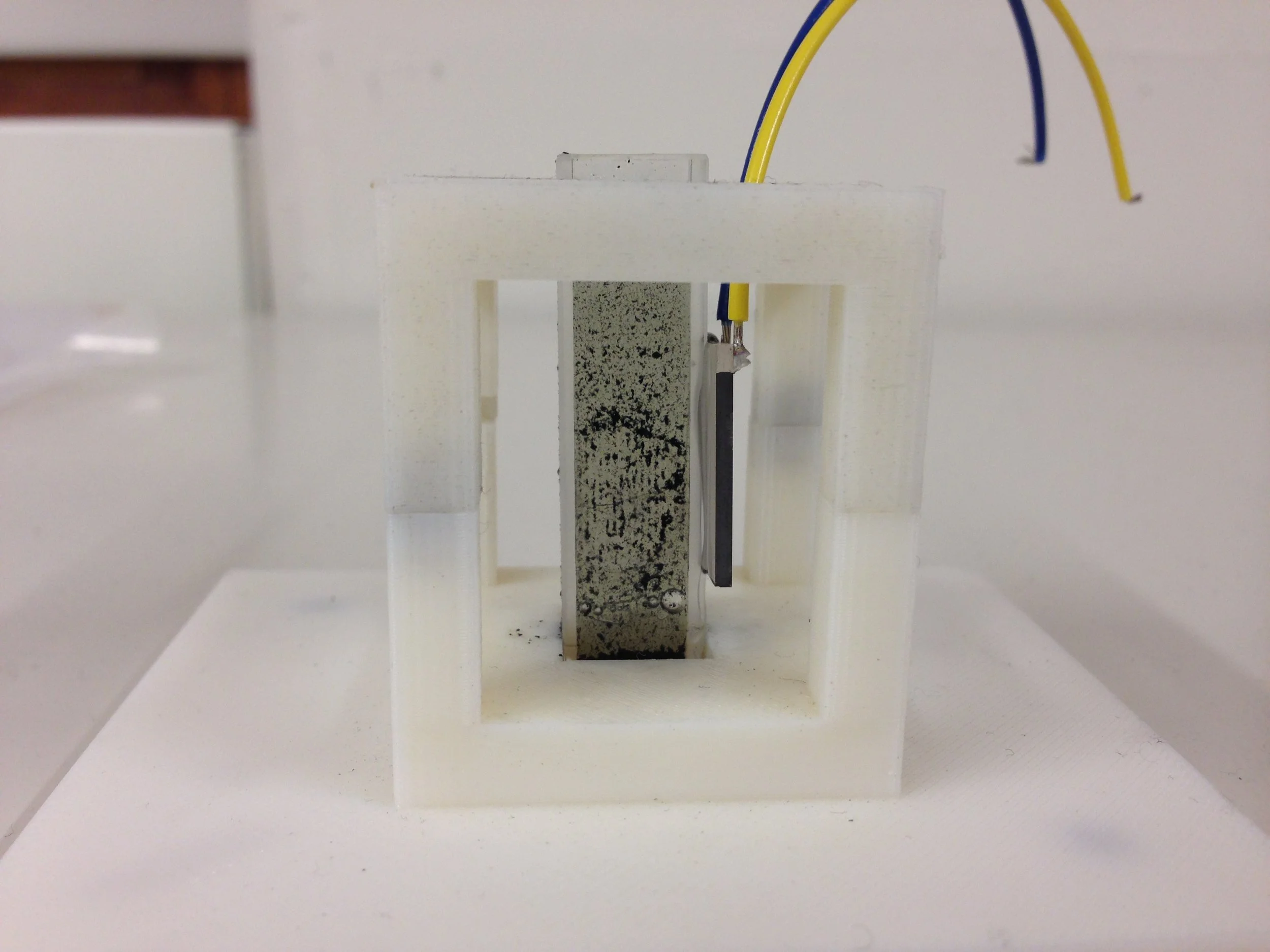

Development and Applications of Acoustic Focusing for Particle Assembly

2024 PhD Thesis (DSpace Link)

Acoustic focusing is a noncontact method for assembling sub-mm particles to create designed composites. In this work, I discuss how acoustic focusing fits in the manufacturing ecosystem of extruded composites and the challenge of balancing assembly precision with speed. I developed strategies for improving assembly speed while bypassing maximum acoustic transducer power limitations.

Precision Origami Folding

Precision Lattice Folding for 2D+ Assembly

September 2013 - August 2015

2015 MSc Thesis (DSpace Link)

Origami structures may be combined with precision 2D assembly methods to enable 2D+ assembly of 3D cell structures. This work explains how to design the structure and its constraints to minimize misalignment errors during folding.

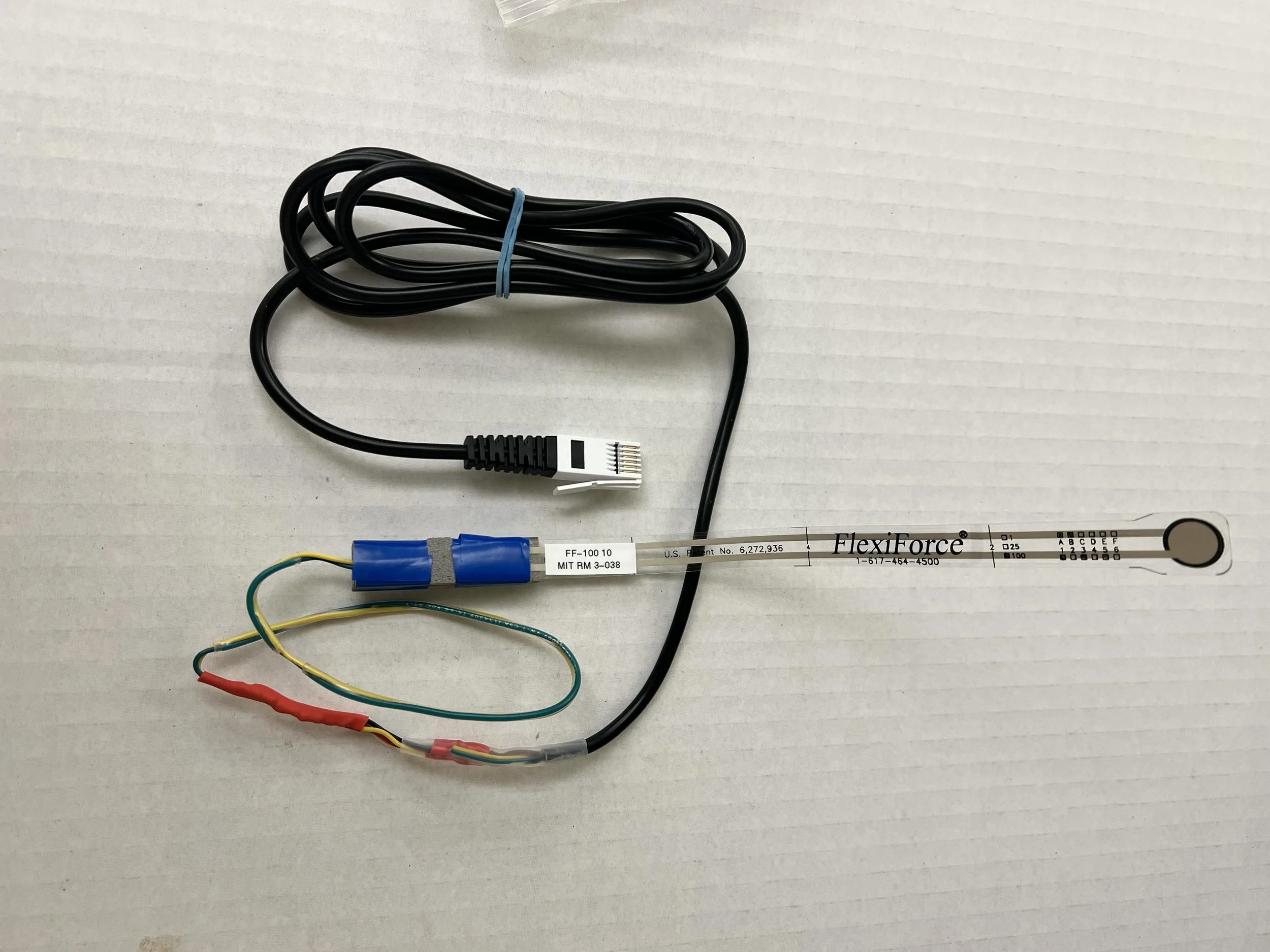

Artery Phantom for Medical Ultrasound

Phantom for validating Medical Ultrasound Blood Pressure Measurements

June 2011 - May 2012

BSc Thesis (DSpace link)

Ultrasound is a benign alternative to cuffs for measuring blood pressure. To validate ultrasound as a blood pressure measurement technique, I designed, prototyped and tested a mechanical phantom that mimicked the mechanical properties of the brachial artery during static and dynamic artery flow.

Solar Car Hub and Spindle

Desktop Lathe

System Model of Linear Stage Friction

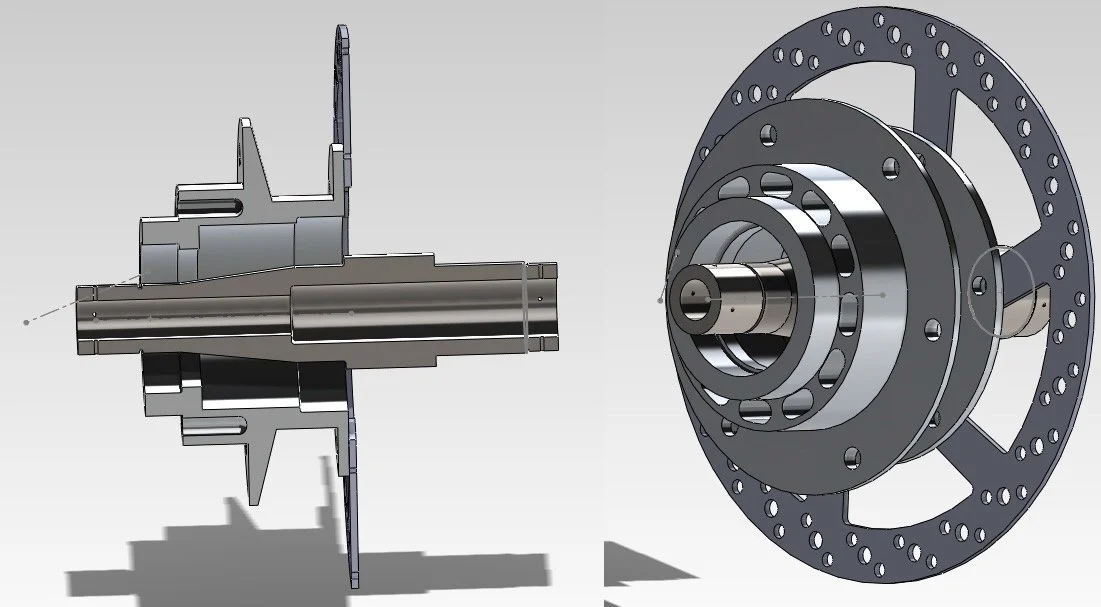

Design/Build Hub and Spindle for Solar Car

October 2011 - May 2012

Project report: PDF link

Design of the wheel hub and spindle of a solar car for the MIT Solar Car Team. The parts were designed to survive multiple races each exceeding 2000 km. The spindle and hub were designed/produced and successfully integrated into Solar Car for the 2012 American Solar Challenge.

Design/Model/Build of Desktop Lathe

February - May 2012

This project was to design and then manufacture a desktop lathe capable of turning aluminum. The lathe also had to survive 1) a fall from ~ a 3-foot height, 2) a hit with a sledgehammer, and 3) ~ a 120-lb static load on the bed.

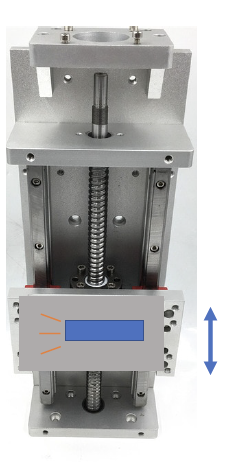

Dynamic Model of Linear Stage undergoing oscillating motion.

November 2018

Dynamic model of linear stage under stop-go motion. Key challenge was to model stiction and kinetic friction alongside the electrical and mechanical components.

Instrumentation/Control

Vibration Isolation of Speaker

Feedback Control Design for Vibration Isolation of Speaker

November 2021

Design/Construction of Feedback Controller to isolate speaker cone from vibrations. The controller system comprises the speaker, filter circuit, LabVIEW controller, and MyRIO interface.

Design/Build of Microcomputer to Control Desktop Lathe

Design/Build of Microcomputer to Control Desktop Lathe

April 2012

Design/Construction of microcomputer to power and control (open-loop) the spindle motor and motors driving the 2-axis bed of a Desktop Lathe.

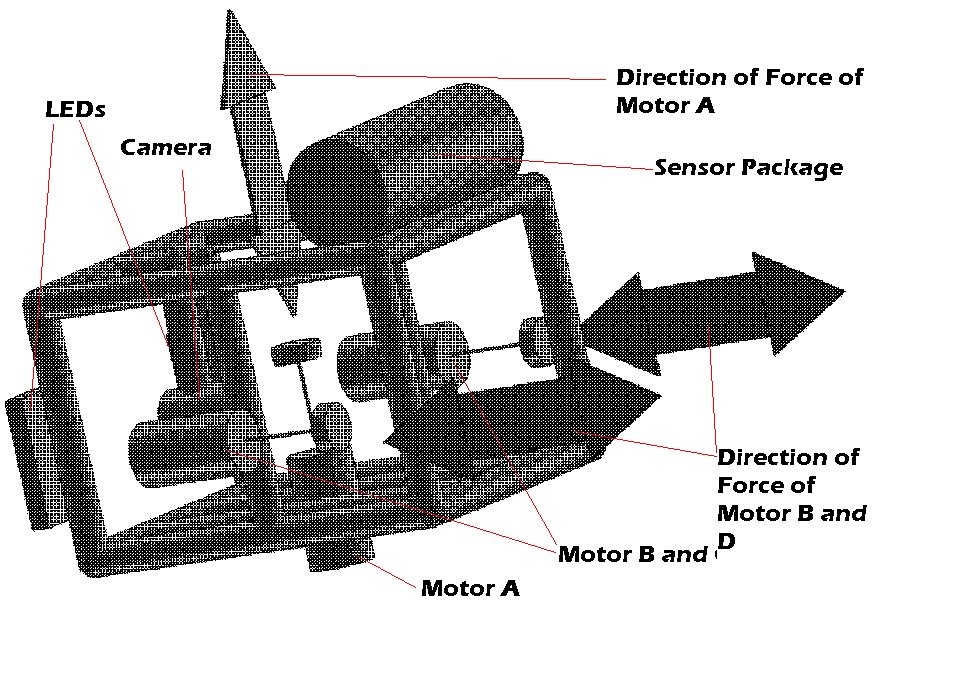

Betty - Aquatic Search Robot

Develop/Deploy Autonomous Robot

February - May 2011

Equip and program an aquatic vehicle (Kingfisher M100) to autonomously search for beacons in Charles River

Boxfish - Underwater ROV

Design/Build Underwater ROV

February - May 2009

Design/Build/Deploy underwater ROV

Shop Skills, Design for Manufacturing

Volume Manufacturing - CNC Design of Injection Molding /Thermoforming Molds

CNC Design of Injection Molding, Thermoforming Molds

February - May 2011

Design/Production of molds for injection molding and thermoforming as part of the Design for Manufacturing Class. Molds were CNC machined on mill and lathe (Mastercam)

CNC Paperweight

Aluminum Paperweight - CNC

February 2011

CNC machining of Aluminum paperweight. Profile was turned on the CNC lathe. The image of the Hyrule crest was CNC milled. CNC programs were created in Mastercam.

TIG Welded Car Chassis

Solar Car Chassis - TIG Welding

June - August 2010

TIG welding the roll cage and car chassis for a Solar Car. The chassis and roll cage were made of steel tubing — chassis design by Mike Roberts. The car was road-tested in the Summer of 2011 and raced in the 2011 World Solar Challenge.

Machined Aluminum Flashlight - Mill, Lathe

Aluminum Flashlight - Mill, Lathe

Fall 2008

Constructed as part of lathe and mill training, MIT Edgerton Student Shop, 2008

Archery

Fence for Outdoor Archery Practice at MIT

Briggs Field Fence - MIT Archery Team Practice

2024 - Designed and built to protect onlookers during archery practice on the mixed-use field at MIT. The fence is 400 feet long and designed to be assembled and disassembled for each practice. This is the only outdoor archery range within 10 miles of central Boston.

Arrow Building

Arrow Building

I build my arrows for practice and tournaments, from cutting the shafts to fletching and point installation. Outdoor arrows are carbon-wrapped aluminum shafts, fletched with vanes. Indoor arrows are aluminum, fletched with feathers.

Bow Maintainance

Tuning, nock tying and wrapping the center serving on bow string.