Acoustic Focusing for High Speed Particle Assembly in Viscous Fluids

PhD in Mechanical Engineering

Acoustic Focusing for Particle Assembly

Acoustic focusing uses sound interference to assemble material in space. The assembly forces depend on the acoustic contrast between the bulk fluid and the contained filler. As a result, this process can assemble across a broad range of sizes (mm to micron) and material types (cells, metals, carbon, oil).

DSPace Link to Thesis: link

Group: Device Realization Lab

PI/Thesis Advisor: Dr. Brian Anthony

-

The challenge of acoustic focusing for assembly, especially in manufacturing, is that common filler particles are small (sub-mm), and common bulk materials are viscous, e.g., thermoplastics. Both attributes of manufacturing processes lead to prohibitively long assembly times. Increased acoustic transducer power can mitigate the slow assembly times but quickly hits a ceiling as this same power drives a disruptive bulk flow that destroys the pattern.

-

The challenge of acoustic focusing for assembly, especially in manufacturing, is that common filler particles are small (sub-mm), and common bulk materials are viscous, e.g., thermoplastics. Both attributes of manufacturing processes lead to prohibitively long assembly times. Increased acoustic transducer power can mitigate the slow assembly times but is quickly limited by a disruptive bulk flow, driven by the same acoustic power, that destroys the pattern.

-

Below are a select list of elements from thesis work.

Proof of Concept: Assembling particles in High Viscosity Fluids

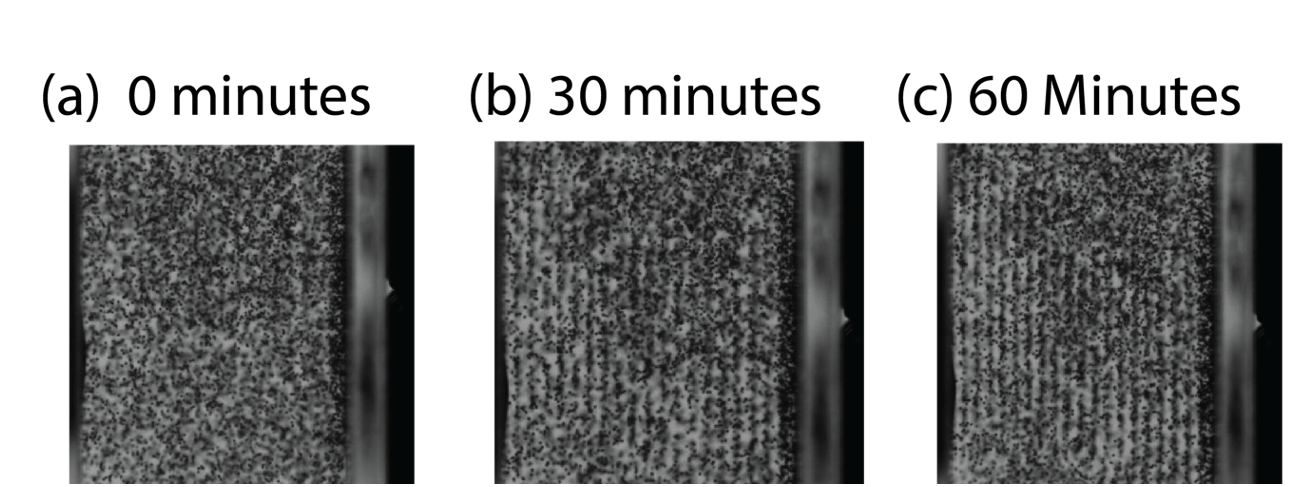

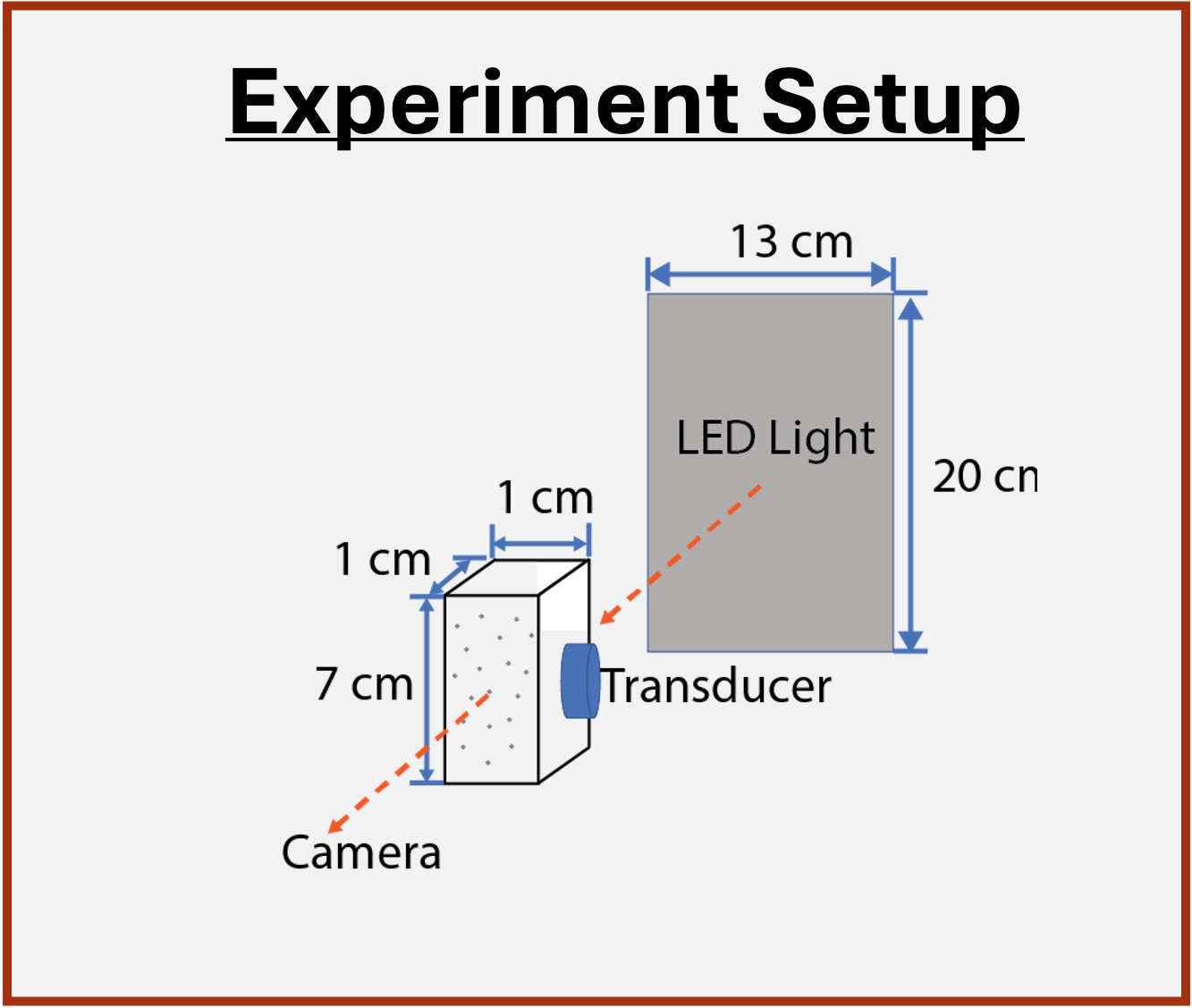

Experiment Setup: Fixture Design, Imaging Equipment Details.

Pulse Echo - Measuring Sound Speed and Attenuation

Assembling Particles to enable conductivity in composites - Proof of Concept, Conductivity Model

Sensitivity Analysis to Determine Relative Power Losses amongst assembly time variables

Patterning in High Viscosity Fluids

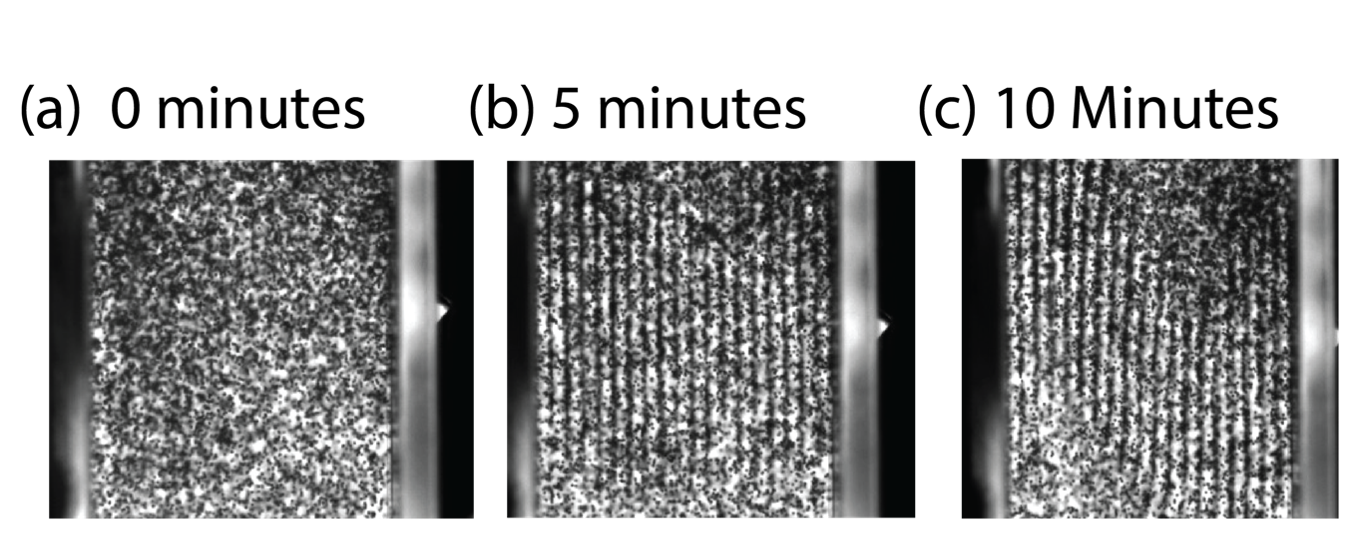

Thermoplastics have high viscosities of 10,000 cSt and greater. These values are several orders of magnitude greater than the fluids typically used in acoustic particle assembly, water, and glycerol, which have 1 - 10 cSt viscosities. Below are images where I demonstrate assembly in 10,000 cSt (left) and 100,000 cSt (right) fluids.

Note: These images are from Fall 2019 and do not represent images from the finalized experimental setup. The original goals of these images were to 1) demonstrate proof of concept and 2) highlight the technical challenges of assembling at higher viscosities. PhD thesis work used data from the 100 - 1000 cSt range.

100 micrometer particles in 10,000 cSt fluid

100 micrometer particles in 100,000 cSt fluid.

Imaging for Quantifying and Tracking Pattern Quality

Fixture Design and Imaging Equipment

September 2019 - March 2020

Schematic of imaging apparatus. Camera records particle pattern of during assembly.

Fixture Design*: a combination of custom (FDM printed, designed in Solidworks) and off-the-shelf parts. The camera is attached to a rail via a Thor Labs micrometer stage. Samples sit on a stack of Thor Labs micrometer stages - two orthogonal stages providing horizontal translation and a rotation stage. The camera rail and stack of stages are bolted to an optical breadboard. The combination of stages enables the camera's X, Y, and Z translation relative to the sample. Angular orientation is assessed using a depth-of-field target on the stage stack.

Camera/Lighting:

Camera Model: Megaspeed MS55k-SC high-speed monochromatic camera.

Lighting: 13 cm vs. 20 cm white LED light, Wall Power

Frame rate: 20 fps, 2 μs exposure time

Depth of Field: 2 mm

*The fixture’s design was iterated from September 2019 through Spring 2020. The final version was completed in March 2020 and provided the data ultimately used in PhD thesis.

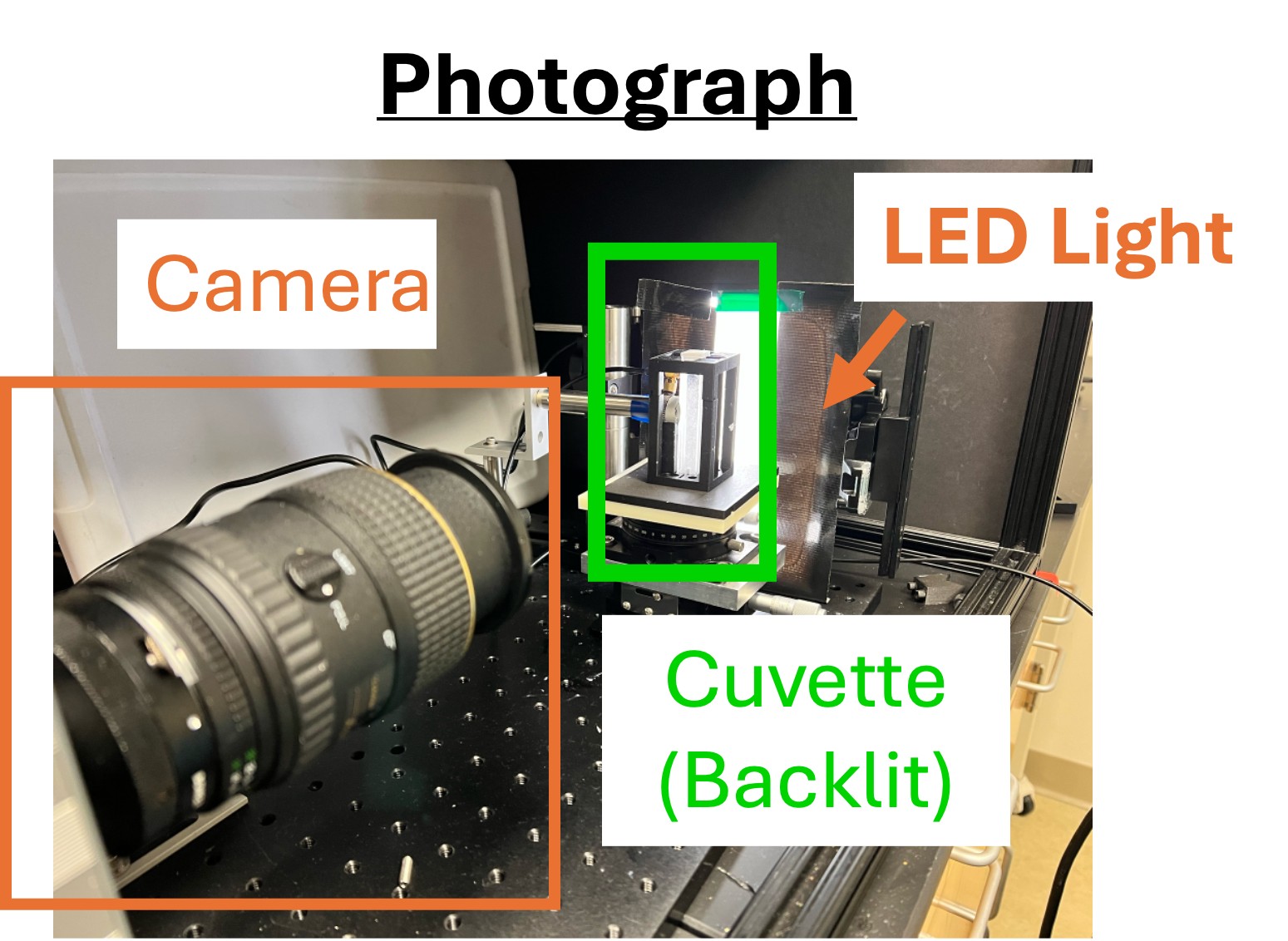

Camera Image Sample

Image of assembled particles as seen by camera

On left - image recorded by camera during particle assembly. Markers on the right of the sample provide the orientation, scale, and location of the region of interest during pre-processing and analysis in MATLAB.

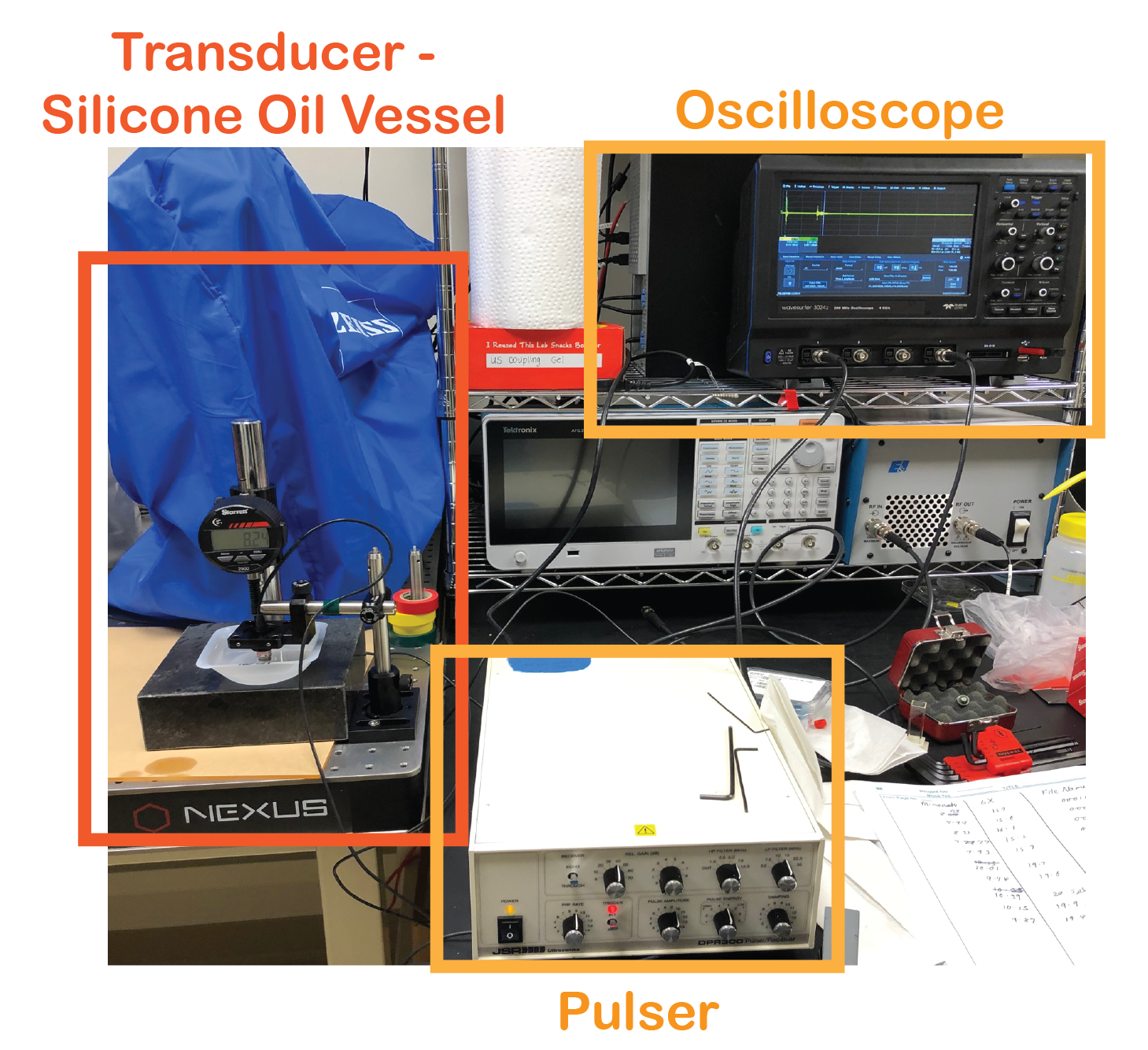

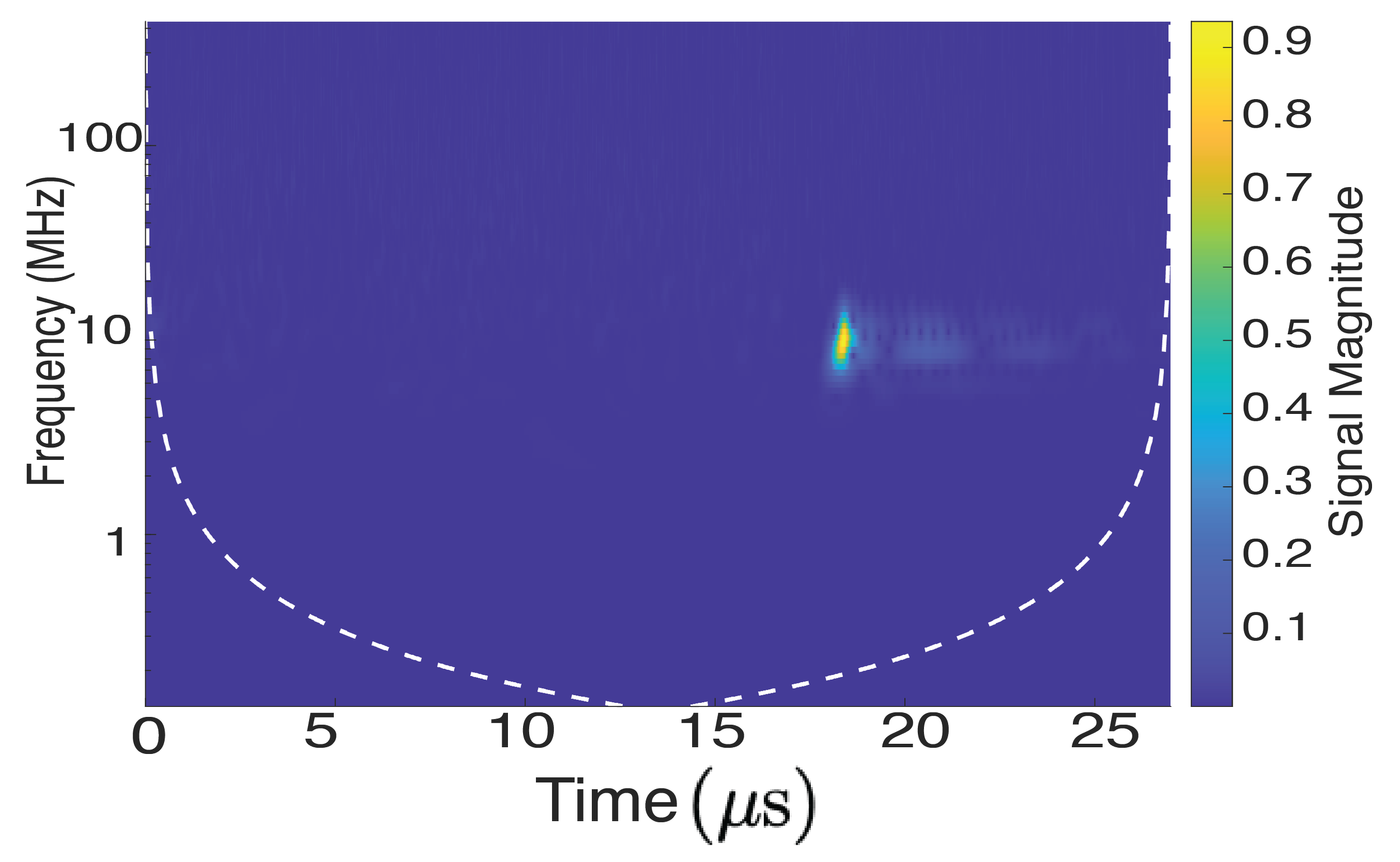

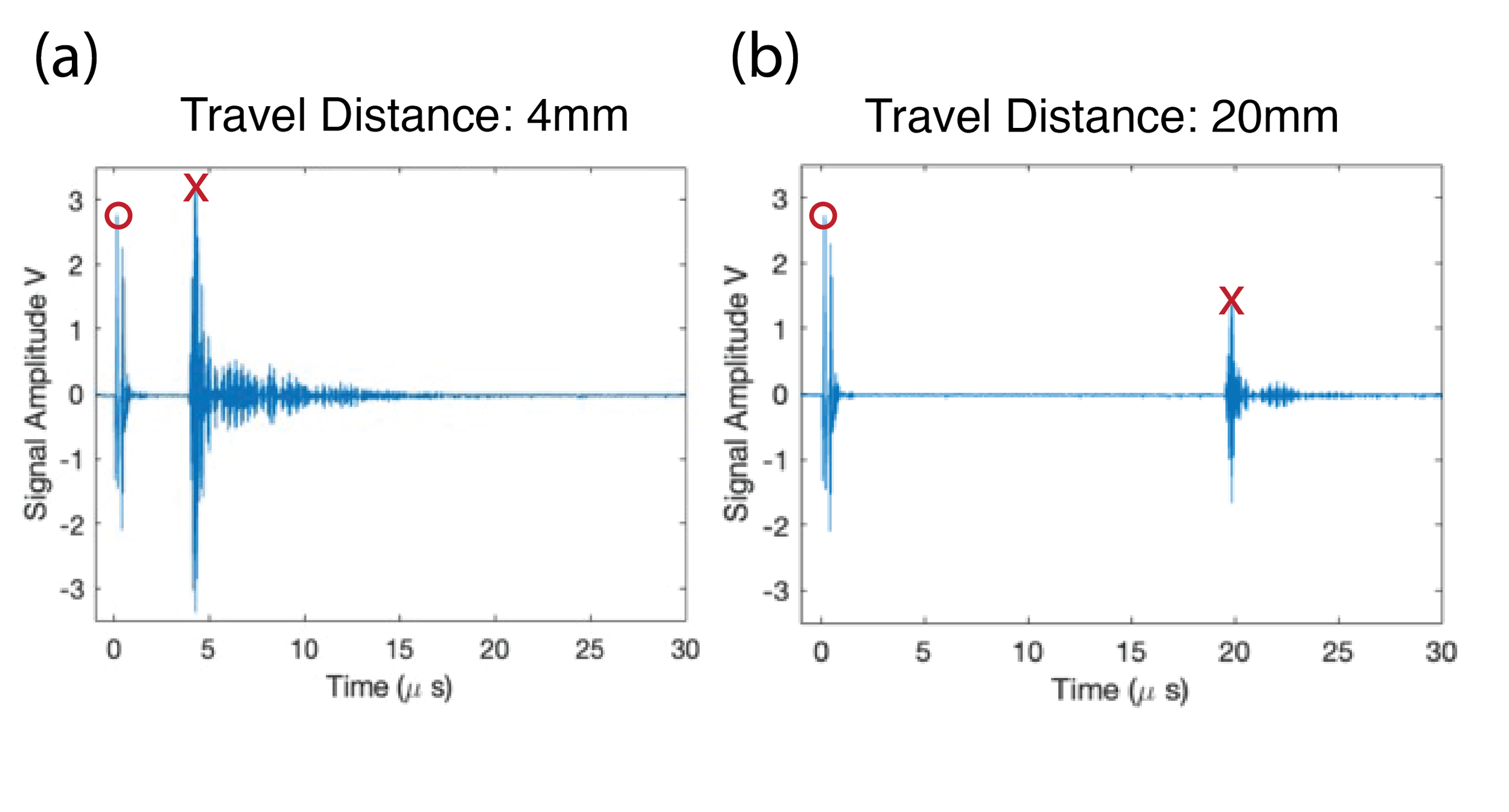

Pulse Echo - Measure Sound Speed and Attenuation

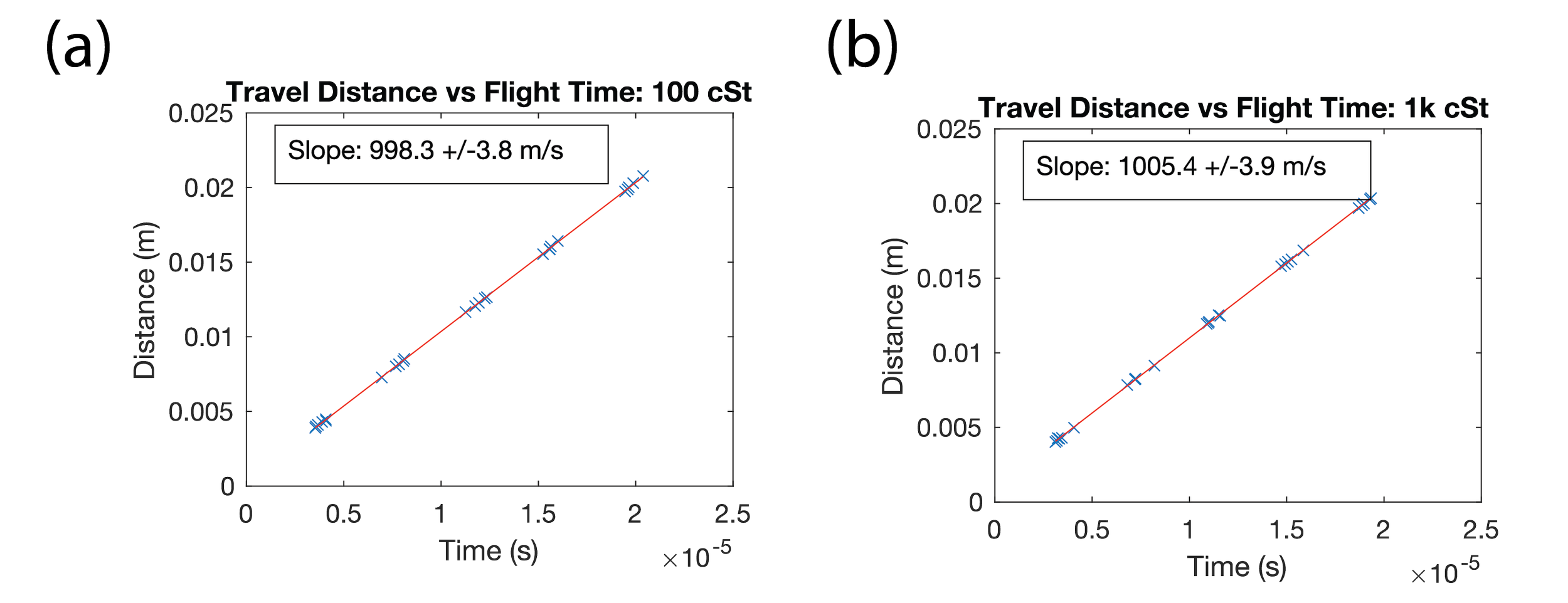

Time of flight measurements to measure material sound speed and attenuation coefficient. A JSR1000 pulser triggers a 10MHz transducer (Olympus Dual Element Transducer). The transducer emits a pulse that reflects off a wall and returns to the transducer. The pulser is connected to a Wavesurfer 3024z oscilloscope, which receives and logs the signal. Data is exported to Matlab for processing.

Acoustic Focusing to Enhance Composite Properties

2016 - 2017

In composite assembly, acoustic focusing enables one to assemble a homogenous material mix into a designed pattern. The designed process has enhanced properties compared to the homogenous mix as it uses the filler properties more effectively - stiffness, strength, and conductivity, to name a few. In this work, I use acoustic focusing to increase the conductivity of a composite.