Acoustic Focusing to Increase Conductivity in Composites

2016-2017

Acoustophoresis aka Acoustic Trapping

Acoustophoresis assembly uses sound interference to create pressure nodes capable of moving objects in space. As a manufacturing technique, it is capable of assembling sub-mm particles into designed structures. The video on the left demonstrates polystyrene particles arranged into parallel bands.

Application - Improve conductivity in structures with conductive fillers in non-conductive bulk material

One application of acoustophoresis in manufacturing is assembling and compacting conductive filler material, such as carbon fiber, silver particles, etc., in bulk material. The result is improved conduction within the composite.

On the right is an image of an early prototype, showing the carbon fiber arranged into parallel bands.

(This work was done as part of PhD)

Organization and Compaction of Composite Filler Material using Acoustic Focusing

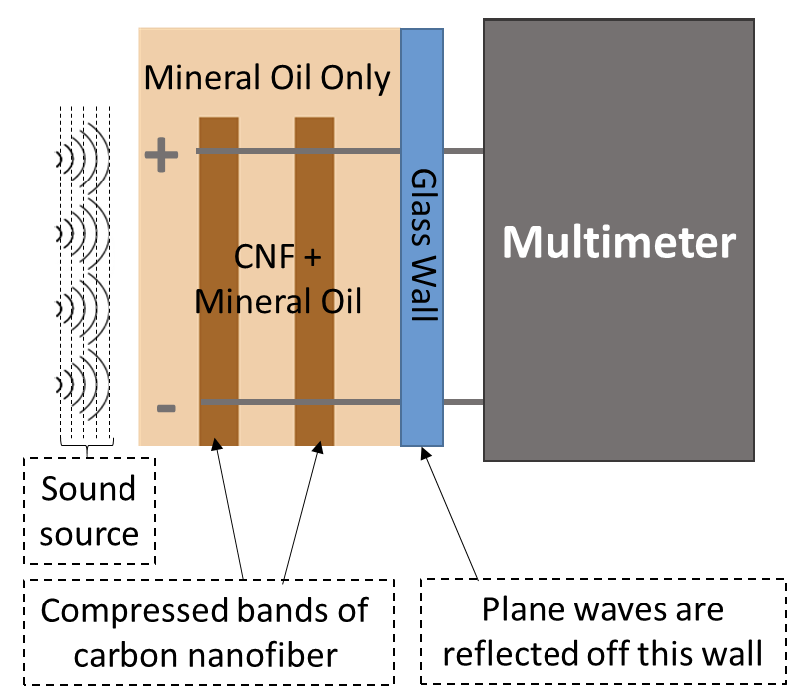

Below is an image showing the measured resistivity of a mineral oil and carbon fiber mixture with acoustic focusing. When the acoustic power turns on and off, the resistance falls and rises with it, to demonstrate how acoustic focusing compacts the filler material.

For information on the experiment and modeling of this behavior, please this link to my ASME Conference Paper (2017).

Schematic of Carbon Nano Fibers in Mineral Oil - Test

Test Results - Toggling transducer power toggled electrical resistance

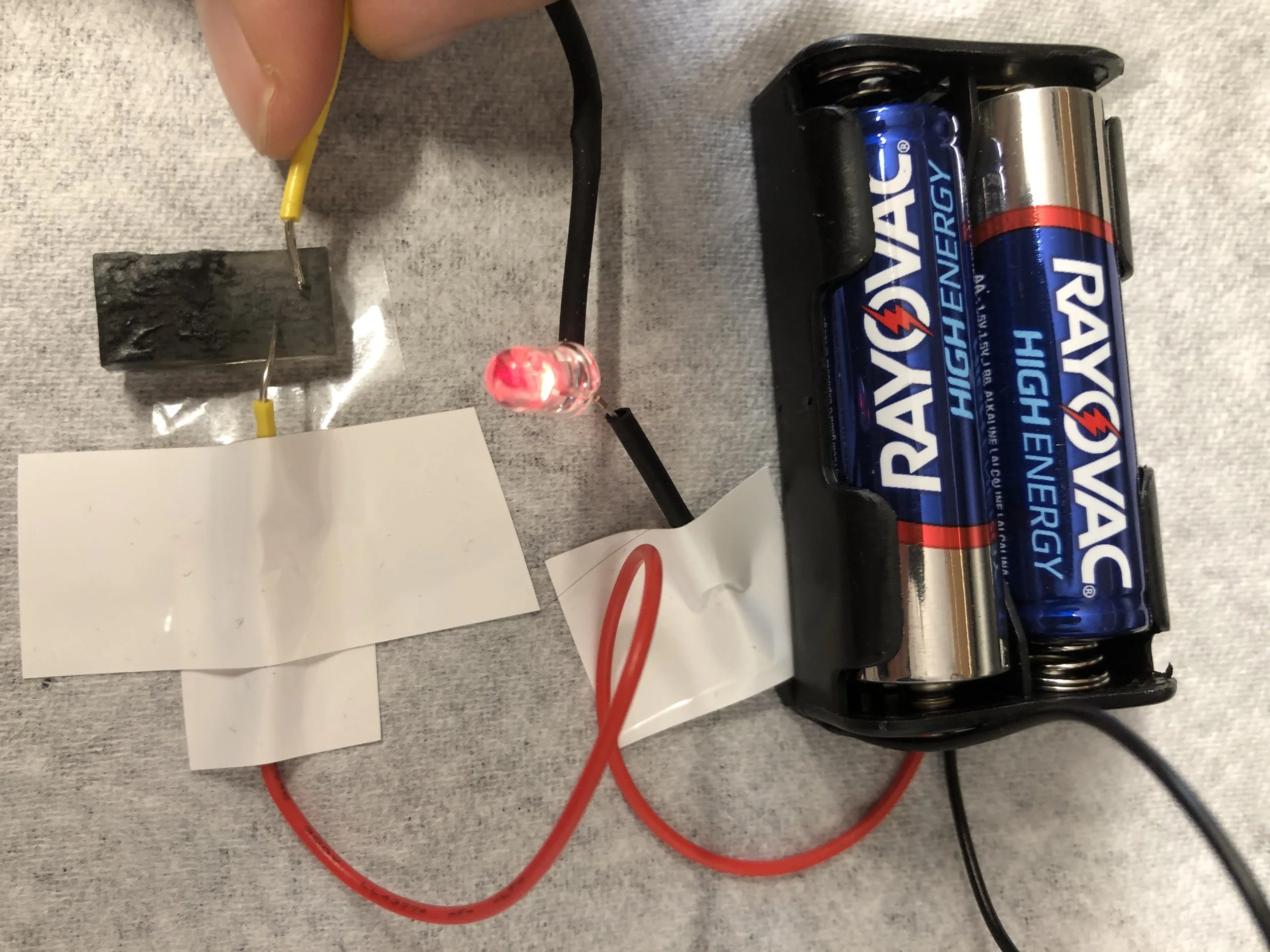

Acoustic Focusing of Carbon Fiber in UV Monomer

Here, I also used acoustic focusing to assemble carbon fiber into bands. In this case, the bulk material was a UV-curable monomer, so that I could lock the pattern in place after assembly. To demonstrate conductivity in the now ‘locked’ bands, I placed wires from an open battery-LED circuit at the top and bottom of the bands, closing the circuit and powering the LED.