Volume Manufacturing of Yo Yo Parts

February - May 2011

The project was to make fifty Yo-Yos using injection molding and thermoforming techniques as part of the Design and Manufacturing II Class at MIT. From this project, I gained hands-on experience with design for thermoforming and injection molding.

-

Teams of students designed their yo-yo according to the theme that semester. My team's yoyo consisted of an injection-molded body, a beaver that fit swung within the body, and a thermoformed cap held in place by a thermoformed ring.

I had full ownership of the thermoformed cap, form CAD to production. I was also responsible for designing the injection molding molds for the body and producing the parts.

We produced 100 pieces per part to make 50 yo-yos.

-

I had complete ownership of the thermoformed cap, including:

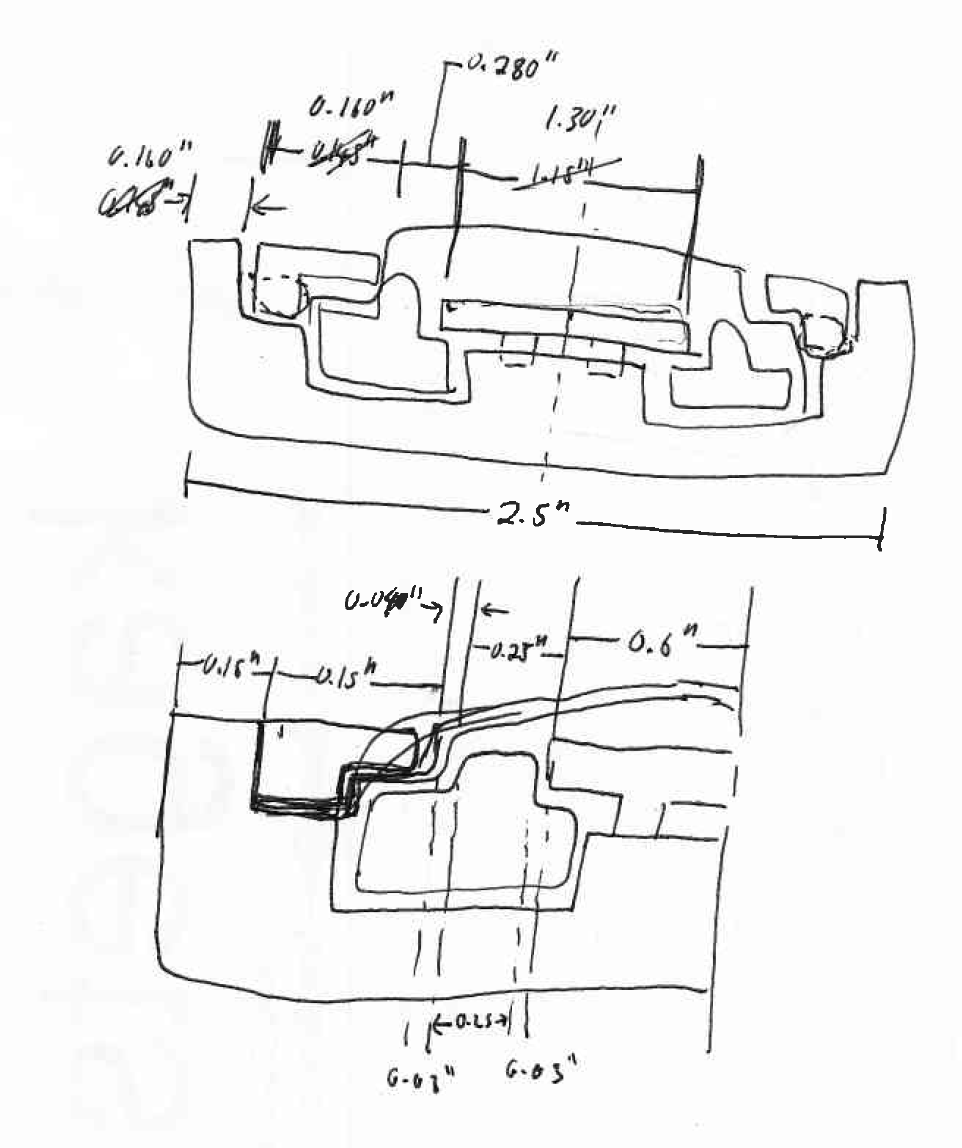

Collaborating with team members to determine key dimensions assembled yo-yo and constituent parts including the cap.

Designed cap part in CAD.

Imported cap's CAD model into Mastercam (CNC mill software). Developed a CNC program for machining cap mold.

Developed mold's machining process plans and part drawings (GD&T) that were approved by the head shop instructor before machining. Executed process plans to mill mold using CNC program.

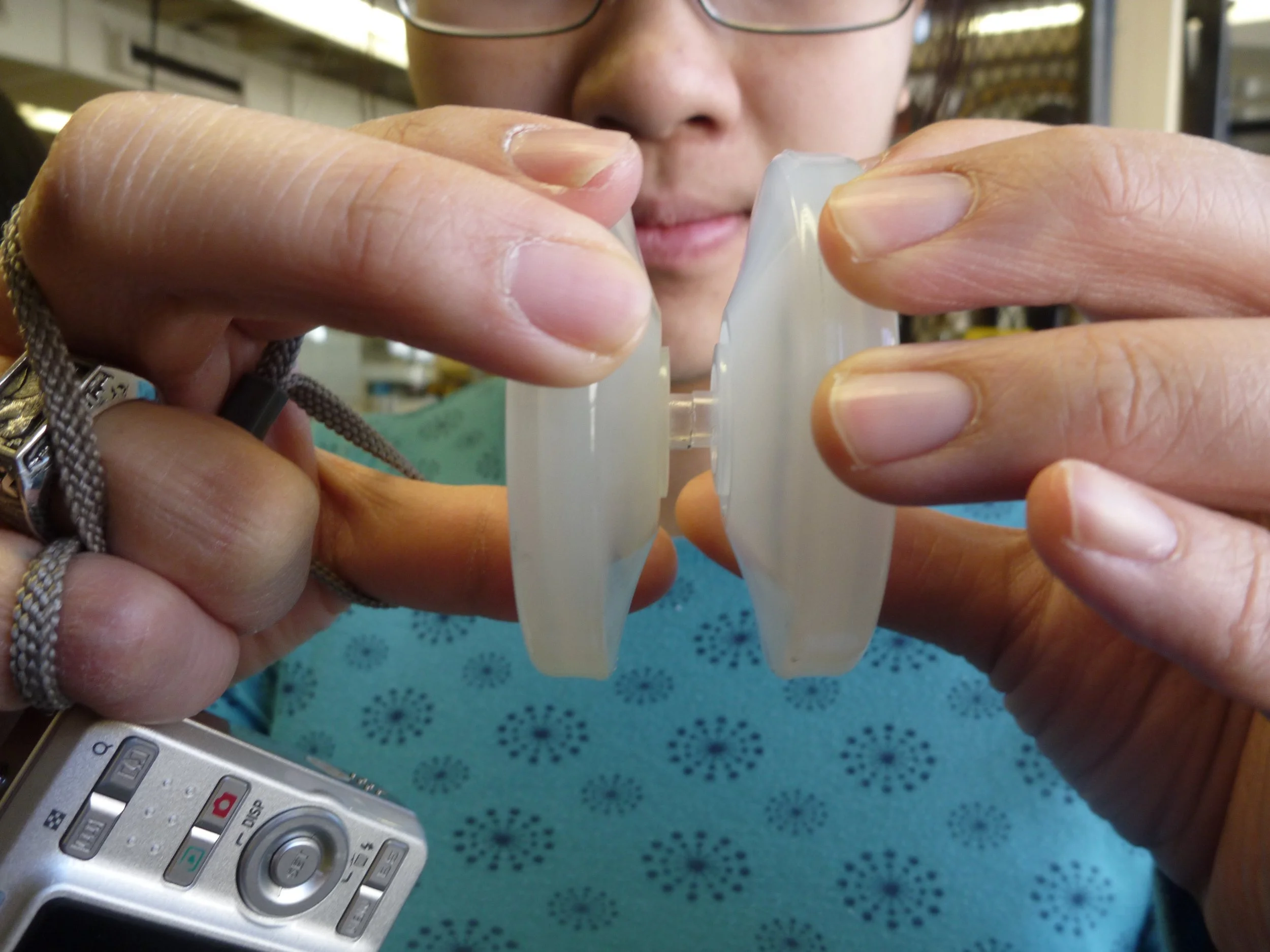

Operated thermoforming machine to produce parts using mold, including parameter optimization and troubleshooting.

Measured key dimensions in the 100 thermoformed caps. Summarized findings as mean values and their standard deviations in the final team report.

-

The yoyo body was initially designed in CAD by a teammate. The CAD model was then handed to me for mold design and part production. My contributions were:

Translated CAD model of part into mold design in Mastercam. Modified key dimensions to account for the injection molding process, including shrinkage and ejection.

Developed CNC program for machining molds. Developed mold's machining process plans and part drawings (GD&T). Plans were approved by the head shop instructor before machining.

Operated mill-to-machine mold using the CNC program.

Operated injection molding machine to produce parts using molds, including parameter optimization and troubleshooting.

Troubleshooted injection molding molds to address flash, combustion, warping, and voids. Solutions included re-machining of existing molds and parameter optimization.

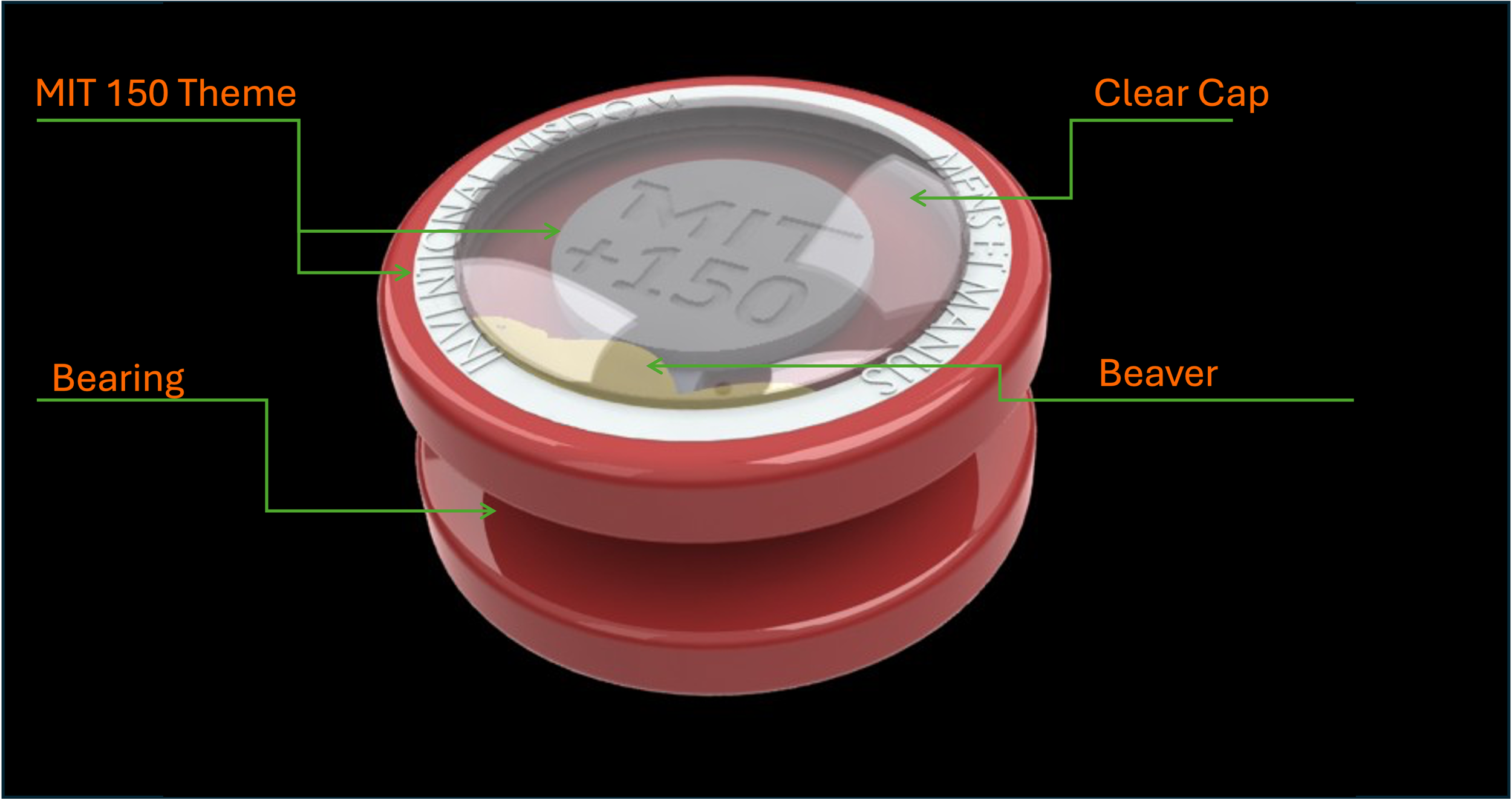

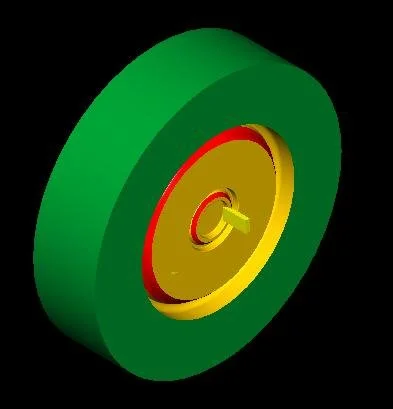

Yoyo Design

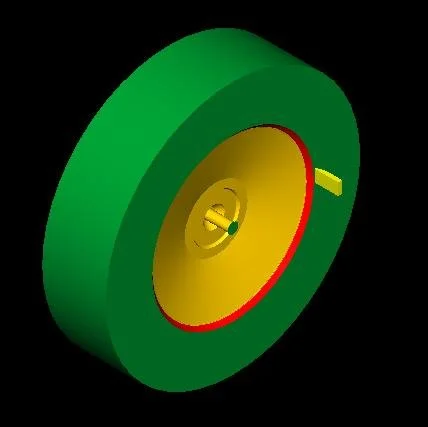

The yoyo consisted of 5 produced parts - 4 injection molded parts and a theromoformed cap. The yoyo body is designed and fitted with an o-ring and bearing for improved yoyo performance.

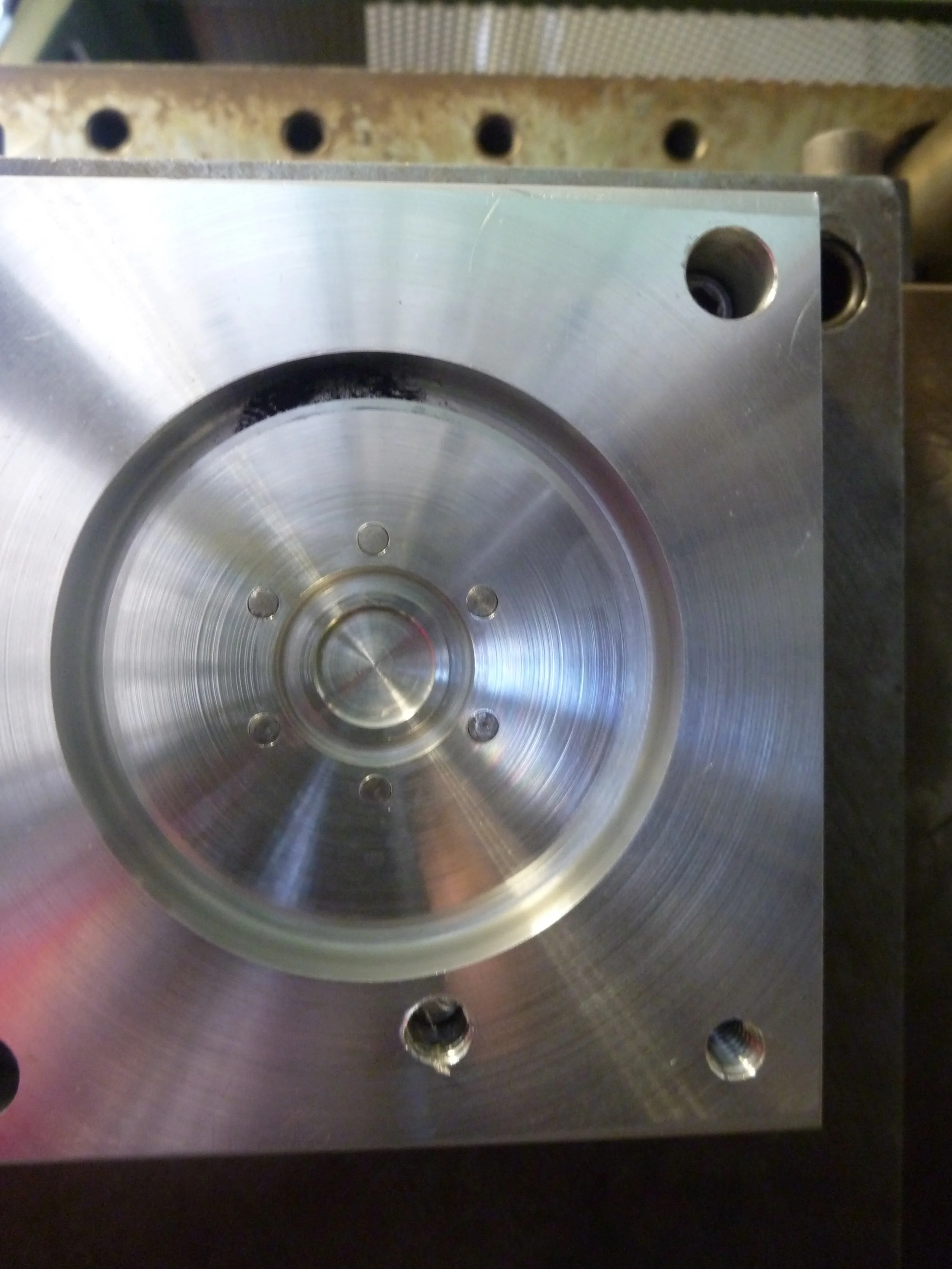

CNC Machining Molds - Injection Molded Yoyo Body and Thermoformed Cap

Yoyo body. Inside are ejector pin marks, which will be hidden under other parts after final assembly. The color is maroon red to match the MIT theme.

Half of clamshell mold used to injection mold body. I milled the mold in aluminum, using CNC program made in Mastercam

Parts: Body (Injection Molding) and Cap (Thermoforming)

Thermoformed Cap, which fits inside rim of body. It is held in place by a injection molded ring (not shown here). The ring was designed and produced by a teammate.